- Introduction

- The Importance of Properly prepreg dry cloth cutting tape

- Common Mistakes in Prepreg prepreg dry cloth cutting tape

- How to Ensure Success with Prepreg Dry Cloth Cutting Tape

- Tips and Tricks for Using Prepreg Dry Cloth Cutting Tape

- Troubleshooting: What to Do If You Encounter Problems

- Conclusion: Why Proper Use of Prepreg Dry Cloth Cutting Tape is Crucial for Success

- FAQ’s

- General Information

- Application and Usage

- Maintenance and Troubleshooting

Introduction

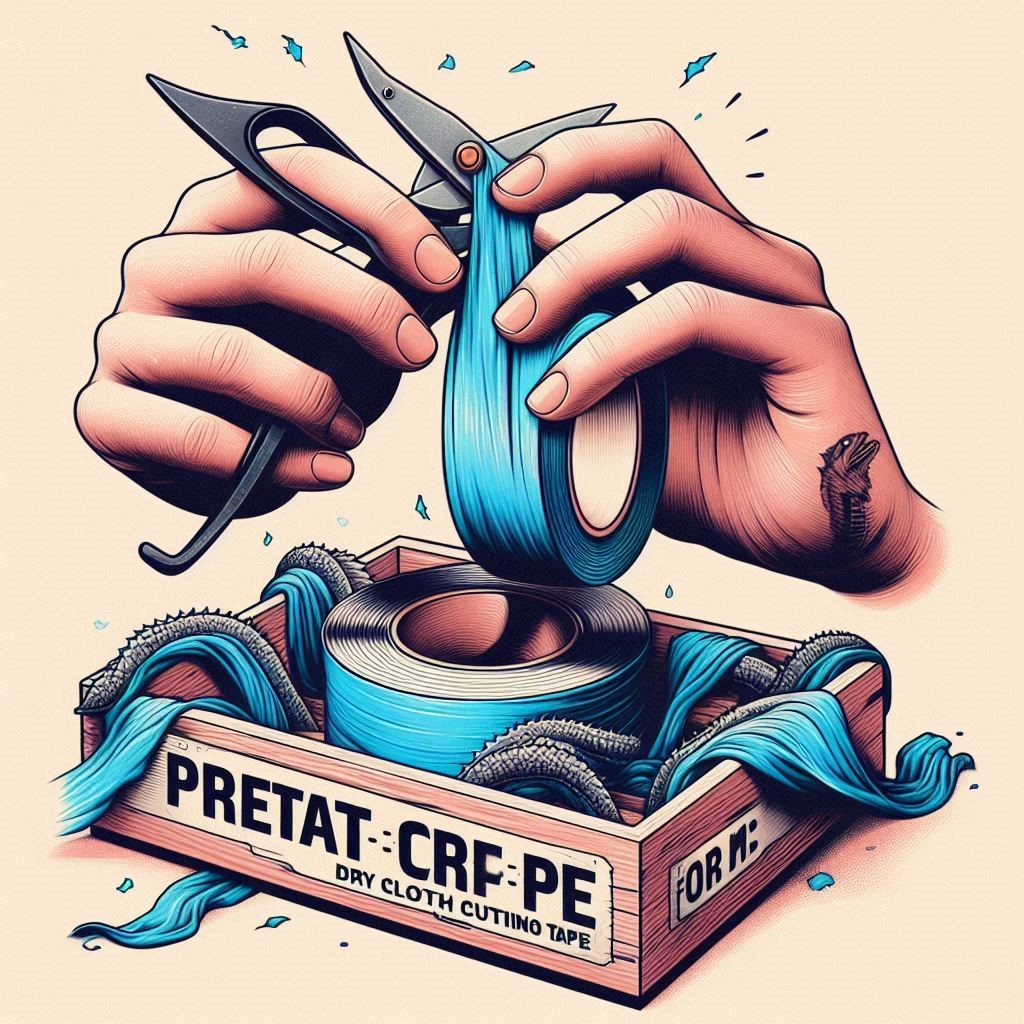

When it comes to precision cutting in the world of composites, few tools are as essential as prepreg dry cloth cutting tape. This seemingly simple adhesive tape plays a crucial role in ensuring that your projects come together seamlessly and effectively. Whether you’re a seasoned professional or just starting out, understanding how to use this tape can make all the difference between success and costly mistakes.

Imagine working painstakingly on your composite components only to have them misaligned due to improper taping techniques. The frustration is real! That’s why mastering prepreg dry cloth cutting tape is not just an option; it’s a necessity for anyone looking to achieve top-notch results. With the right approach, you can streamline your workflow and avoid common pitfalls that lead to wasted materials and time.

Dive into this guide as we explore everything from its importance to troubleshooting tips—arming you with the knowledge needed for successful projects using prepreg dry cloth cutting tape. Get ready to enhance your skills and elevate your craftsmanship!

The Importance of Properly prepreg dry cloth cutting tape

Using properly prepreg dry cloth cutting tape is crucial in the composite manufacturing process. It serves as a reliable guide, ensuring clean and precise cuts that maintain the integrity of your materials.

When cut accurately, each layer aligns perfectly. This precision enhances adhesion when layers are bonded together. Misalignment can lead to structural weaknesses and costly rework.

Additionally, high-quality cutting tape prevents fraying or curling at the edges. This not only preserves the aesthetic quality but also reduces wastage during production.

Many underestimate its role in achieving uniform pressure distribution across surfaces during curing. Proper application of cutting tape contributes significantly to overall product strength and performance.

Investing time in selecting and utilizing appropriate dry cloth cutting tape pays off in durability and effectiveness down the line. Secure your success by prioritizing this essential component from start to finish.

Common Mistakes in Prepreg prepreg dry cloth cutting tape

One of the most frequent mistakes is using the wrong type of tape. Not all tapes are designed for prepreg materials, and this can lead to issues with adhesion.

Another common error is improper application technique. Applying too much pressure can damage the fibers, while insufficient pressure may result in poor bonding.

Many overlook surface preparation as well. Dust or contaminants on the cloth can interfere with how effectively the tape holds, leading to failures down the line.

Timing also plays a critical role. Using tape that has expired or been improperly stored might compromise its effectiveness during cutting processes.

Some users underestimate the importance of temperature control. Extreme heat or cold can affect both the tackiness and performance of dry cloth cutting tape significantly.

How to Ensure Success with Prepreg Dry Cloth Cutting Tape

To ensure success with dry cloth cutting tape, start by selecting the right type for your project. Different applications might require specific tape characteristics, so do your research.

Before cutting, take time to prepare the workspace. A clean and organized area will help prevent errors and distractions during the process.

When applying the tape, use even pressure. This ensures that it adheres properly without bubbling or lifting at the edges. Cutting should be done steadily; sharp blades yield cleaner lines and reduce fraying.

Always test on a small piece first if you’re unsure about a technique or material compatibility. This simple step can save you from costly mistakes later.

Patience is key! Rushing through each stage increases the risk of problems down the line. Take your time to get everything just right for optimal results with prepreg dry cloth cutting tape.

Tips and Tricks for Using Prepreg Dry Cloth Cutting Tape

When using dry cloth cutting tape, preparation is key. Start by ensuring your work surface is clean and free from debris. This simple step can prevent contamination and ensure a smooth application.

Cut the tape into manageable lengths. Smaller pieces are easier to handle and allow for greater precision when securing fabric layers together.

Apply even pressure while laying down the tape to eliminate air bubbles. A bubble-free application helps maintain accuracy during cutting.

Consider using a sharp cutter or scissors designed specifically for this material. Dull blades can lead to fraying, which compromises the integrity of your cut sections.

Experiment with different techniques on scrap materials before tackling your main project. This practice will help you discover what works best for you, enhancing both confidence and skill in handling dry cloth cutting tape effectively.

Troubleshooting: What to Do If You Encounter Problems

When using dry cloth cutting tape, issues can arise unexpectedly. One common problem is poor adhesion. If the tape isn’t sticking well to the material, check for surface cleanliness. Dust or oils can compromise its effectiveness.

Another frequent issue is uneven cuts. This often stems from a dull knife blade. Ensure your tools are sharp and in good condition before starting any project.

If you notice fraying at the edges of your cuts, consider adjusting your technique. A steady hand and consistent pressure can make all the difference in achieving clean lines.

Should you encounter bubbles trapped under the tape, simply lift it gently and reapply while smoothing out any air pockets as you go along.

Staying calm during these hiccups helps maintain focus on finding solutions rather than getting frustrated by setbacks.

Conclusion: Why Proper Use of Prepreg Dry Cloth Cutting Tape is Crucial for Success

Using prepreg dry cloth cutting tape correctly can make a significant difference in the quality and precision of your work. When applied properly, this tape helps to maintain the integrity of materials during cutting processes, ensuring clean edges and reducing waste.

Mistakes with dry cloth cutting tape can lead to costly errors. From misalignment to uneven cuts, these issues often stem from improper handling or application techniques. By understanding common pitfalls and how to avoid them, you set yourself up for success.

Incorporating best practices into your workflow not only enhances efficiency but also boosts confidence in your results. Whether it’s using sharp tools or keeping surfaces clean, every detail counts when working with this specialized material.

Troubleshooting is essential as well; knowing what steps to take if something goes wrong can save both time and resources. Regularly assessing your process allows for continuous improvement.

The importance of proper use cannot be overstated—it impacts everything from project timelines to final product quality. Adopting a mindful approach will undoubtedly elevate your craft and ensure that you achieve exceptional outcomes each time you utilize prepreg dry cloth cutting tape.

FAQ’s

General Information

Prepreg dry cloth cutting tape is a specialized adhesive tape used in the aerospace and composite industries. It’s designed to cut through prepreg materials, which are pre-impregnated with resin, allowing for precise and clean cuts without damaging the underlying material.

This tape is primarily used for cutting and trimming prepreg fabrics in the production of composite parts. It helps ensure accurate, clean cuts, which are essential for the quality and performance of composite components in aerospace, automotive, and other high-tech industries.

Prepreg dry cloth cutting tape is specifically engineered to handle the unique properties of prepreg materials, which are often more challenging to cut than standard fabrics. It has specialized adhesive properties that prevent residue and ensure clean, precise cuts.

Application and Usage

To apply, position the tape on the prepreg material where you want to make the cut. Press down firmly to ensure it adheres well. Use a sharp blade or rotary cutter to slice through the tape and prepreg fabric. After cutting, carefully remove the tape to avoid any damage to the material.

While it’s designed for use with a variety of prepreg materials, it’s always best to check the manufacturer’s recommendations for compatibility. Some high-performance prepreg materials might require specific types of cutting tape for optimal results.

Store the tape in a cool, dry place away from direct sunlight and moisture. Proper storage helps preserve the adhesive properties and ensures the tape remains effective for its intended use.

Maintenance and Troubleshooting

If residue is left behind, gently clean the area with a suitable solvent recommended for prepreg materials. Always test the solvent on a small, inconspicuous area first to ensure it does not damage the prepreg fabric.

Ensure that the surface of the prepreg material is clean and dry before applying the tape. If the tape begins to curl, use a tape dispenser with tension control or apply the tape in smaller sections to reduce the risk of peeling.

Prepreg dry cutting tape is generally designed for single-use to ensure optimal performance. Reusing it may compromise the cutting quality and the integrity of the prepreg material.

Common issues include adhesive residue, tape curling, and difficulty adhering to certain prepreg surfaces. Address these by ensuring proper application techniques, using a sharp cutting tool, and selecting the right type of tape for your specific prepreg material. If problems persist, consult with the tape manufacturer for further advice.